After 50 Years, Lean Manufacturing Is Ready to Take the Next Step Towards Global Performance

By looking at the bigger picture, Enterprise Lean Planning is revolutionizing the way companies plan, decide, orchestrate, invest, sell, promote, recruit and exercise control over their value chain.

scroll down

|

After 50 Years, Lean Manufacturing

Is Now Ready to Take the Next Step

Towards Global Performance

By looking at the bigger picture, Enterprise Lean Planning is revolutionizing

the way companies plan, decide, orchestrate, invest, sell, promote, recruit

and exercise control over their value chain.

scroll down

|

Enterprise Lean Planning

The answer to many challenges of our times

The new Enterprise Lean Planning management system is a pragmatic response to the many challenges companies are facing today. Challenges including carbon footprint reduction, uncertainty, reduced time-to-market, resource rarefaction, process complexity, regulations and ethical responsibility, to name a few.

By optimizing decision-making at the different strategic, operational and tactical levels of the company, Enterprise Lean Planning uncovers performance gains that were lying at the heart of non-optimized and non-integrated planning processes.

Make the most of all your resources

By abandoning cost-based logic and embracing one based on value, companies and shareholders will also use the ground-breaking simulation capabilities ELP offers. The way they conceive and implement their strategies is thus improved, whether it is association with investments, human resources, new product introductions, marketing or procurement.

By dynamically interconnecting the various upstream and downstream information data flows, ELP also enables better use of existing ERP systems. It makes the existing investments in ERP systems more profitable and in turn, reduces their TCO.

A paradigm shift that benefits all stakeholders

By allowing company members to concentrate on value-added tasks, offering them stability in task execution, better balancing professional and personal lives, or allowing them to devote more time to training, ELP not only fosters well-being at work, but it also creates the conditions for long-term performance.

Unlike “zero-sum game” logic, the paradigm shift introduced by the ELP management system demonstrates that an approach to management revisited through the perspective of the rapid sharing of information, the rational use of resources, and adherence to PDCA cycles, can benefit all stakeholders.

The advantages that this new management system generates for company members therefore do not arise at the expense of other categories of stakeholders. Instead, they propagate throughout the company and have a positive impact on the interests of all, whether they are employees, executives, managers, shareholders, suppliers, or customers.

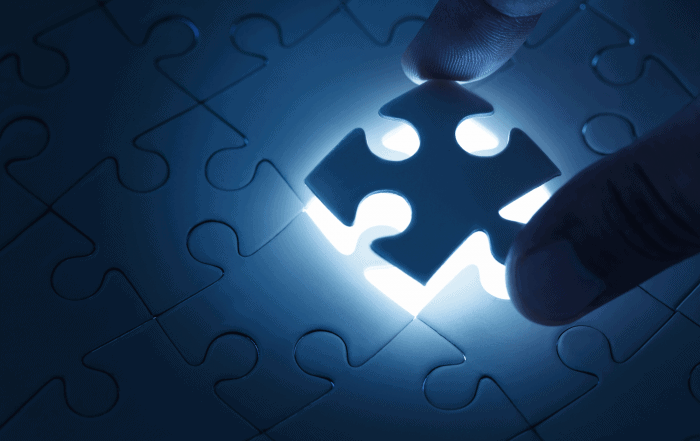

A compass and a map to guide your transformations

With the help of the ELP system, the company’s transformation is now perceived from an overall performance point of view, making each stage of the transformation a lever for reaching global performance, and not an end in itself.

The implementation of the ELP management system acts both as a compass and a map. This is because it sets the course (moving towards Global Performance), and provides the order of priority in which the different transformation actions must be undertaken.

Enterprise Lean Planning

The answer to many challenges of our times

Get new performance gains from your planning processes

The new Enterprise Lean Planning management system is a pragmatic response to the many challenges companies are facing today. Challenges including carbon footprint reduction, uncertainty, reduced time-to-market, resource rarefaction, process complexity, regulations and ethical responsibility, to name a few.

By optimizing decision-making at the different strategic, operational and tactical levels of the company, Enterprise Lean Planning uncovers performance gains that were lying at the heart of non-optimized and non-integrated planning processes.

By abandoning cost-based logic and embracing one based on value, companies and shareholders will also use the ground-breaking simulation capabilities ELP offers. The way they conceive and implement their strategies is thus improved, whether it is association with investments, human resources, new product introductions, marketing or procurement.

A paradigm shift that benefits all stakeholders

By dynamically interconnecting the various upstream and downstream information data flows, ELP also enables better use of existing ERP systems. It makes the existing investments in ERP systems more profitable and in turn, reduces their TCO.

By allowing company members to concentrate on value-added tasks, offering them stability in task execution, better balancing professional and personal lives, or allowing them to devote more time to training, ELP not only fosters well-being at work, but it also creates the conditions for long-term performance.

Unlike “zero-sum game” logic, the paradigm shift introduced by the ELP management system demonstrates that an approach to management revisited through the perspective of the rapid sharing of information, the rational use of resources, and adherence to PDCA cycles, can benefit all stakeholders.

A compass and a map to guide your transformations

The advantages that this new management system generates for company members therefore do not arise at the expense of other categories of stakeholders. Instead, they propagate throughout the company and have a positive impact on the interests of all, whether they are employees, executives, managers, shareholders, suppliers, or customers.

With the help of the ELP system, the company’s transformation is now perceived from an overall performance point of view, making each stage of the transformation a lever for reaching global performance, and not an end in itself.

The implementation of the ELP management system acts both as a compass and a map. This is because it sets the course (moving towards Global Performance), and provides the order of priority in which the different transformation actions must be undertaken.

INDUSTRIES

Where we excel

INDUSTRIES

Where we excel

New Product Entry

Plan your design offices as well as the prototyping, industrialization and production phases in a fully integrated way.

Life Sciences

Plan your development project teams, your laboratories, your certification teams, and your units dedicated to clinical studies.

Manufacturing

Reduce bottlenecks associated with complex processes, juggle transitory demand, & optimize purchasing and stockpiling.

CASE STUDIES

Our experience

Pfizer selects PlanningForce to plan and schedule its Phase 1 clinical studies at its two sites in New Haven (USA) and Anderlecht (Belgium). Implementation takes place in 2020.

BLOG

Related Articles

The Rise of Algorithms in Management

Algorithms are becoming more and more preponderant in management. It is therefore crucial to avoid missteps and to be well guided in the forest of management algorithms.

Eliminating the new Enterprise MUDAS – Facilitated by ELP – part 1

This article presents the six new types of MUDAS that Enterprise Lean Planning addresses to complement those identified and combated by Lean Manufacturing.

The Importance of Identifying Critical Roles within an Organization

This article sheds light on the importance of considering critical roles and resources alongside critical tasks in the knowledge-based economy.