L3 – Operational Steering

Operational steering is in charge of implementing tactical planning while dealing with the hazards of day-to-day production management.

scroll down

|

L3 – Operational Steering

Operational steering is in charge of implementing tactical planning while dealing with the hazards of day-to-day production management.

Solutions

Operational steering

Operational Steering is focused on carrying out business activities in conformity with what has been defined at the tactical planning stage. It consists of the functions of operational planning and progress, seeking to optimize how resource capabilities can best achieve goals while respecting operational constraints.

“Postponing deadlines is no longer an option. PlanningForce helps us find the right resources and has the agility to find creative and effective solutions.”

Line managers and team leaders develop agile management techniques while staying in tune with the company’s overall goals.

The way in which the tactical plan is created gives line managers and team leaders the autonomy to organize daily tasks through the preparation of a detailed operational plan. This operational plan reflects the fine-tuning of the tasks and operations that need to be carried out to achieve the production objectives set for them. This takes into account the capacity limits of operational resources and production risks. Rapid feedback on the progress of tasks also promotes the implementation of agile management techniques.

Line managers and team leaders develop agile management techniques while staying in tune with the company’s overall goals.

The way in which the tactical plan is created gives line managers and team leaders the autonomy to organize daily tasks through the preparation of a detailed operational plan. This operational plan reflects the fine-tuning of the tasks and operations that need to be carried out to achieve the production objectives set for them. This takes into account the capacity limits of operational resources and production risks. Rapid feedback on the progress of tasks also promotes the implementation of agile management techniques.

L3 – Operational Steering

Business operations are in good hands

Operational Planning

The operational planning is the short-term portion of tactical planning. It is as detailed as possible. Team leaders then know exactly what operations should be carried out, in what time frame, in what order, and what materials to use.

It is based on the use of the PlanningForce’s planning engine, configured to reflect the specific rules of different companies and their industries.

The concrete implementation of this operational planning will be based on a visual publication, where the mode and format are adapted according to the stakeholder and their needs.

The plan is also made available simultaneously across the different operational departments and hierarchical levels so that an identical version of the plan can circulate throughout the company.

Activity Progress

The progress of activities is recorded by consolidating data automatically collected from workstations or equipment or manually collected by operators using the PlanningForce execution monitoring tools set up in Level 4 – Execution.

Collecting and consolidating progress as activities occur allows the line manager and team leaders to take the necessary steps to reprioritize activities or reallocate resources in an agile manner. This helps the achievement of goals set by the Operations Managers at the tactical level.

The progress is expressed in units of measurement that are most relevant to identifying the actual progress of the activities. These units can include the time spent on tasks (which gives the time remaining), but also parts (good and scrap), pallets, kilograms, liters, etc.

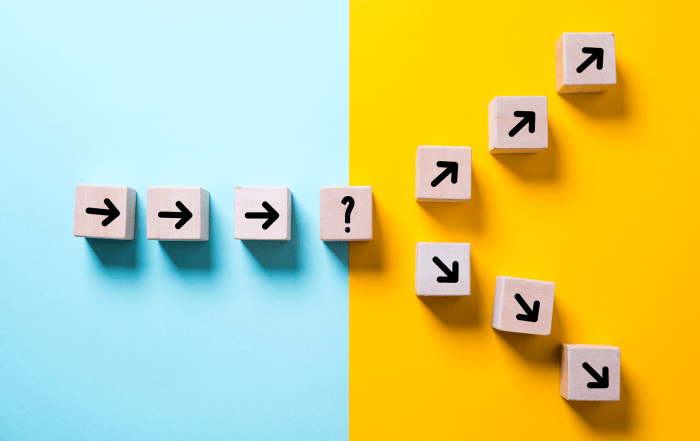

Managing Change

Modifications may be made to the operational plan, taking into account any contingencies that would require a change in the priorities of task execution.

PlanningForce records disruptive events that occur at the executional level and proposes operational changes that can help to minimize the effects of these disruptions on the entire value chain. If the impact of the disruptions proves to be too great, the tactical steering cycle can be shortened to allow a new global plan to be recalculated.

Disruptive events are recorded and categorized in order to establish statistics based on their frequency and the type of impact that they have. This makes it possible to identify areas for process improvement. It also facilitates the adaptation to risk and uncertainty coefficients present at the tactical level accordingly.

L3 – Operational Steering

Business operations are in good hands

Operational Planning

The operational planning is the short-term portion of tactical planning. It is as detailed as possible. Team leaders then know exactly what operations should be carried out, in what time frame, in what order, and what materials to use.

It is based on the use of the PlanningForce’s planning engine, configured to reflect the specific rules of different companies and their industries.

The concrete implementation of this operational planning will be based on a visual publication, where the mode and format are adapted according to the stakeholder and their needs.

The plan is also made available simultaneously across the different operational departments and hierarchical levels so that an identical version of the plan can circulate throughout the company.

Activity Progress

The progress of activities is recorded by consolidating data automatically collected from workstations or equipment or manually collected by operators using the PlanningForce execution monitoring tools set up in Level 4 – Execution.

Collecting and consolidating progress as activities occur allows the line manager and team leaders to take the necessary steps to reprioritize activities or reallocate resources in an agile manner. This helps the achievement of goals set by the Operations Managers at the tactical level.

The progress is expressed in units of measurement that are most relevant to identifying the actual progress of the activities. These units can include the time spent on tasks (which gives the time remaining), but also parts (good and scrap), pallets, kilograms, liters, etc.

Managing Change

Modifications may be made to the operational plan, taking into account any contingencies that would require a change in the priorities of task execution.

PlanningForce records disruptive events that occur at the executional level and proposes operational changes that can help to minimize the effects of these disruptions on the entire value chain. If the impact of the disruptions proves to be too great, the tactical steering cycle can be shortened to allow a new global plan to be recalculated.

Disruptive events are recorded and categorized in order to establish statistics based on their frequency and the type of impact that they have. This makes it possible to identify areas for process improvement. It also facilitates the adaptation to risk and uncertainty coefficients present at the tactical level accordingly.

BLOG

Related Articles

Eliminating the new Enterprise MUDAS – Facilitated by ELP – part 2

Misuse of knowledge and know-how, the inefficiency of the S&OP process and the lack of agility in managing the R&D project portfolio lead to waste for companies.

Why management techniques must (always) be questioned

Deming and Öno revolutionized the way of producing. While paying tribute to them, this article shows that each era brings new challenges in terms of management.

Operational Steering and Task Execution Monitoring assisted by PlanningForce

Operational Steering focuses on carrying out business activities across all departments in conformity with what is defined at the stage of tactical planning.

More SOLUTIONS

What fits to your needs